CNC milling txheej txheem

Kev tswj cov lej (tseem siv computer lej tswj, thiab feem ntau hu ua CNC) yog kev tswj hwm ntawm cov cuab yeej siv tshuab (xws li kev xyaum, tshuab dhos, mills thiab 3D tshuab luam ntawv) los ntawm lub computer.Lub tshuab CNC ua cov khoom siv (hlau, yas, ntoo, ceramic, lossis cov khoom sib xyaw) kom ua tau raws li cov lus qhia tshwj xeeb los ntawm kev ua raws li cov lus qhia uas tau teev tseg thiab tsis muaj tus neeg siv phau ntawv ncaj qha tswj kev ua haujlwm.

Lub tshuab CNC yog cov cuab yeej siv lub cev muaj zog thiab feem ntau yog lub tshuab tsav tsheb, uas yog ob qho tib si tswj los ntawm lub computer, raws li cov lus qhia tshwj xeeb.Cov lus qhia raug xa mus rau lub tshuab CNC nyob rau hauv daim ntawv ntawm ib tug sequential kev pab cuam ntawm lub tshuab tswj cov lus qhia xws li G-code thiab M-code, ces tua.Qhov kev zov me nyuam tuaj yeem sau los ntawm ib tus neeg lossis, ntau zaus, tsim los ntawm graphical computer-aided design (CAD) software thiab / lossis computer aided manufacturing (CAM) software.Nyob rau hauv rooj plaub ntawm 3D tshuab luam ntawv, qhov yuav tsum tau luam tawm yog "sliced", ua ntej cov lus qhia (los yog qhov kev pab cuam) yog generated.3D tshuab luam ntawv kuj siv G-Code.

CNC yog ib qho kev txhim kho loj tshaj qhov tsis siv computer machining uas yuav tsum tau tswj manually (xws li siv cov cuab yeej xws li tes log lossis levers) lossis mechanically tswj los ntawm pre-fabricated qauv qhia (cams).Nyob rau hauv niaj hnub CNC systems, tus tsim ntawm ib tug neeg kho tshuab ib feem thiab nws cov kev pab cuam yog heev automated.Ib feem lub tshuab ntsuas qhov ntev yog txhais siv CAD software thiab tom qab ntawd muab txhais ua cov lus qhia kev tsim khoom siv computer-aided manufacturing (CAM) software.Cov lus qhia tshwm sim tau hloov pauv (los ntawm "post processor" software) rau hauv cov lus txib tshwj xeeb tsim nyog rau ib lub tshuab tshwj xeeb los tsim cov khoom thiab tom qab ntawd muab tso rau hauv lub tshuab CNC.

Txij li txhua qhov tshwj xeeb yuav tsum tau siv ntau yam cuab yeej sib txawv - xyaum, saws, thiab lwm yam - cov tshuab niaj hnub feem ntau muab ntau yam cuab yeej rau hauv ib qho "cell".Hauv lwm qhov kev teeb tsa, ntau lub tshuab sib txawv yog siv nrog tus tswj hwm sab nraud thiab tib neeg lossis cov neeg ua haujlwm neeg hlau uas txav cov khoom ntawm lub tshuab mus rau lub tshuab.Nyob rau hauv ob qho tib si, cov kauj ruam uas yuav tsum tau ua los tsim ib feem yog automated thiab tsim ib feem uas zoo sib xws rau thawj CAD daim duab.

Milling yog txheej txheem txiav uas siv lub tshuab txiav milling kom tshem tawm cov khoom tawm ntawm qhov chaw ua haujlwm.Lub milling cutter yog cov cuab yeej ua teb, feem ntau nrog ntau cov ntsiab lus txiav.Raws li qhov tsis zoo rau kev drilling, qhov twg cov cuab yeej tau nce siab raws nws txoj kev sib hloov axis, lub cutter hauv milling feem ntau yog txav mus rau nws qhov axis kom txiav tshwm sim ntawm lub voj voog ntawm lub cutter.Raws li cov milling cutter nkag mus rau hauv cov khoom ua haujlwm, cov npoo txiav (flutes lossis cov hniav) ntawm cov cuab yeej rov txiav rau hauv thiab tawm ntawm cov khoom, shaving tawm chips (swarf) los ntawm cov khoom ua haujlwm nrog txhua qhov dhau los.Qhov kev txiav txim yog shear deformation;cov khoom raug thawb tawm ntawm cov khoom ua haujlwm hauv cov pob me me uas dai ua ke kom ntau dua lossis tsawg dua (nyob ntawm cov khoom siv) los tsim cov chips.Qhov no ua rau hlau txiav me ntsis txawv (hauv nws cov tshuab) los ntawm kev txiav cov ntaub ntawv softer nrog cov hniav.

Cov txheej txheem milling tshem tawm cov khoom los ntawm kev ua ntau yam sib cais, txiav me me.Qhov no yog ua tiav los ntawm kev siv lub tshuab txiav nrog ntau cov hniav, tig lub cutter ntawm kev kub ceev, los yog nce cov khoom los ntawm lub cutter maj mam;feem ntau nws yog qee qhov sib xyaw ntawm peb txoj hauv kev no.[2]Qhov ceev thiab pub siv yog sib txawv kom haum rau kev sib xyaw ua ke ntawm qhov sib txawv.Qhov ceev ntawm cov khoom nce mus los ntawm lub tshuab txiav yog hu ua tus nqi pub, lossis tsuas yog pub;Nws yog feem ntau ntsuas raws li nyob rau hauv ib lub sij hawm (ntiv tes ib feeb [in / min los yog ipm] los yog millimeters ib feeb [mm/min]), txawm hais tias nyob deb li ib kiv puag ncig los yog ib tug cutter hniav kuj muaj qee zaum siv.

Muaj ob chav kawm loj ntawm cov txheej txheem milling:

1.Nyob rau hauv lub ntsej muag milling, kev txiav txim tshwm sim feem ntau ntawm cov ces kaum kawg ntawm lub milling cutter.Lub ntsej muag milling yog siv los txiav cov chaw tiaj tus (lub ntsej muag) rau hauv cov khoom ua haujlwm, lossis txiav cov kab noj hniav hauv qab.

2.Nyob rau hauv peripheral milling, qhov txiav txiav tshwm sim feem ntau raws li qhov ncig ntawm lub cutter, yog li ntawd tus ntoo khaub lig seem ntawm milled nto xaus tau txais cov duab ntawm lub cutter.Hauv qhov no, cov hniav ntawm lub tshuab txiav tuaj yeem pom tias yog khawb tawm cov khoom los ntawm cov khoom ua haujlwm.Peripheral milling yog qhov zoo rau kev txiav cov qhov sib sib zog nqus, xov, thiab iav hniav.

| CNC tshuab | Kev piav qhia |

| Mill | Txhais cov kev pab cuam uas muaj cov lej tshwj xeeb thiab cov ntawv kom txav cov ntxaiv (lossis workpiece) mus rau ntau qhov chaw thiab qhov tob.Feem ntau siv G-code.Cov haujlwm muaj xws li: lub ntsej muag milling, lub xub pwg milling, tapping, drilling thiab qee qhov muab tig.Niaj hnub no, CNC mills tuaj yeem muaj 3 txog 6 axes.Feem ntau CNC mills yuav tsum tau muab lub workpiece rau los yog nyob rau hauv lawv thiab yuav tsum yog tsawg kawg yog loj li lub workpiece, tab sis cov tshiab 3-axis tshuab tau tsim uas me npaum li cas. |

| Tshuab dhos | Txiav workpieces thaum lawv tig.Ua kom ceev ceev, precision txiav, feem ntau siv cov cuab yeej indexable thiab xyaum xyaum.Siv tau rau cov kev kawm nyuaj tsim los ua cov khoom uas yuav ua tsis tau rau ntawm phau ntawv tshuab dhos.Cov kev tswj zoo sib xws rau CNC mills thiab feem ntau tuaj yeem nyeem G-code.Feem ntau muaj ob lub axes (X thiab Z), tab sis cov qauv tshiab muaj ntau lub axes, tso cai rau kev ua haujlwm siab dua los ua tshuab. |

| Plasma cutter | Kev txiav cov khoom siv lub teeb plasma.Feem ntau siv los txiav hlau thiab lwm yam hlau, tab sis tuaj yeem siv rau ntau yam khoom siv.Hauv cov txheej txheem no, cov pa roj (xws li compressed cua) yog tshuab ntawm kev kub ceev tawm ntawm lub nozzle;Nyob rau tib lub sijhawm, ib qho hluav taws xob arc yog tsim los ntawm cov pa roj los ntawm lub nozzle mus rau qhov chaw raug txiav, tig qee cov roj mus rau plasma.Lub plasma yog kub txaus kom yaj cov khoom raug txiav thiab txav ceev txaus kom tshuab molten hlau kom deb ntawm qhov txiav. |

| Electric paug machining | (EDM), tseem hu ua spark machining, spark eroding, burning, tuag sinking, los yog hlau yaig, yog ib tug txheej txheem tsim nyob rau hauv uas ib tug xav tau zoo yog tau siv hluav taws xob tawm (sparks).Cov khoom raug tshem tawm los ntawm lub workpiece los ntawm ib tug series ntawm recurring tam sim no tawm ntawm ob electrodes, sib cais los ntawm ib tug dielectric kua thiab raug rau ib tug hluav taws xob voltage.Ib qho ntawm cov electrodes yog hu ua cov cuab yeej electrode, los yog tsuas yog "tawv" lossis "electrode," thaum lwm qhov hu ua workpiece electrode, lossis "workpiece". |

| Multi-spindle tshuab | Hom ntsia hlau tshuab siv hauv ntau lawm.Pom tau tias muaj txiaj ntsig zoo los ntawm kev nce cov khoom lag luam los ntawm automation.Muaj peev xwm txiav cov ntaub ntawv mus rau hauv cov khoom me me thaum tib lub sijhawm siv cov cuab yeej sib txawv.Multi-spindle machines muaj ntau spindles ntawm lub nruas uas tig rau ntawm kab rov tav lossis ntsug.Lub nruas muaj lub laum lub taub hau uas muaj ntau cov spindles uas tau muab tso rau ntawm pob bearings thiab tsav los ntawm lub zog.Muaj ob hom kev txuas rau cov laum lub taub hau, kho lossis kho tau, nyob ntawm seb qhov chaw nyob deb ntawm qhov drilling spindle xav tau ntau yam. |

| Hlau EDM | Kuj tseem hu ua hlau txiav EDM, xaim hluav taws xob EDM, lossis cov xaim mus ncig EDM, cov txheej txheem no siv cov hluav taws xob yaig rau lub tshuab lossis tshem tawm cov khoom siv los ntawm cov khoom siv hluav taws xob, siv cov hlau electrode mus ncig.Cov hlau electrode feem ntau muaj tooj dag- lossis zinc-coated tooj dag cov khoom.Hlau EDM tso cai rau ze li ntawm 90-degree fab thiab siv lub siab me ntsis ntawm cov khoom.Txij li thaum cov hlau yog eroded nyob rau hauv cov txheej txheem no, ib tug hlau EDM tshuab pub cov hlau tshiab los ntawm ib tug spool thaum chopping li siv cov hlau thiab tso rau hauv ib lub thoob rau recycling. |

| Sinker EDM | Kuj hu ua kab noj hniav hom EDM lossis ntim EDM, lub tshuab nqus dej EDM muaj cov khoom siv hluav taws xob thiab cov khoom ua haujlwm hauv cov roj lossis lwm cov kua dej dielectric.Cov electrode thiab workpiece txuas nrog lub zog tsim nyog, uas ua rau muaj hluav taws xob muaj peev xwm ntawm ob qhov chaw.Raws li cov electrode mus txog lub workpiece, dielectric breakdown tshwm sim nyob rau hauv cov kua ua ib tug plasma channel thiab me me spark jumps.Ntau lawm tuag thiab pwm feem ntau ua nrog sinker EDM.Qee cov ntaub ntawv, xws li cov ntaub ntawv mos ferrite thiab epoxy-nplua nuj bonded magnetic cov ntaub ntawv tsis sib xws nrog sinker EDM vim lawv tsis yog hluav taws xob conductive.[6] |

| Dej dav hlau cutter | Kuj tseem hu ua "waterjet", yog cov cuab yeej muaj peev xwm hlais rau hauv cov hlau lossis lwm yam khoom siv (xws li granite) los ntawm kev siv lub dav hlau dej ntawm qhov siab tshaj plaws thiab siab, los yog sib tov dej thiab cov khoom siv abrasive, xws li xuab zeb.Nws yog feem ntau siv thaum lub sij hawm fabrication los yog tsim cov khoom rau machinery thiab lwm yam khoom siv.Waterjet yog txoj kev nyiam thaum cov ntaub ntawv raug txiav yog rhiab rau qhov kub thiab txias uas tsim los ntawm lwm txoj kev.Nws tau pom cov ntawv thov hauv ntau qhov kev lag luam los ntawm mining mus rau aerospace qhov twg nws yog siv rau kev khiav hauj lwm xws li txiav, shaping, carving, thiab reaming. |

CNC drilling tshuab

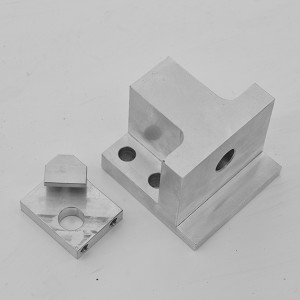

ntu

CNC tshuab dhos

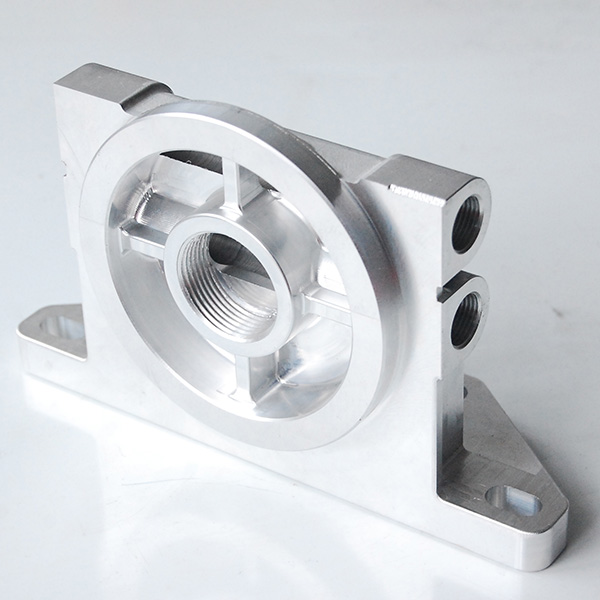

aluminium qhov chaw

CNC machining

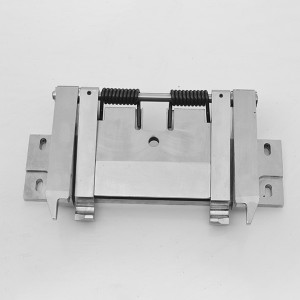

khoov qhov chaw

CNC machining qhov chaw

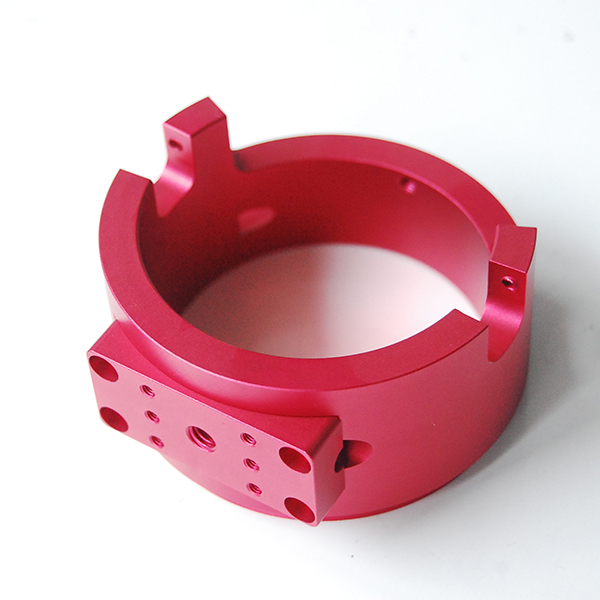

nrog anodizing

High precision

cnc ntu

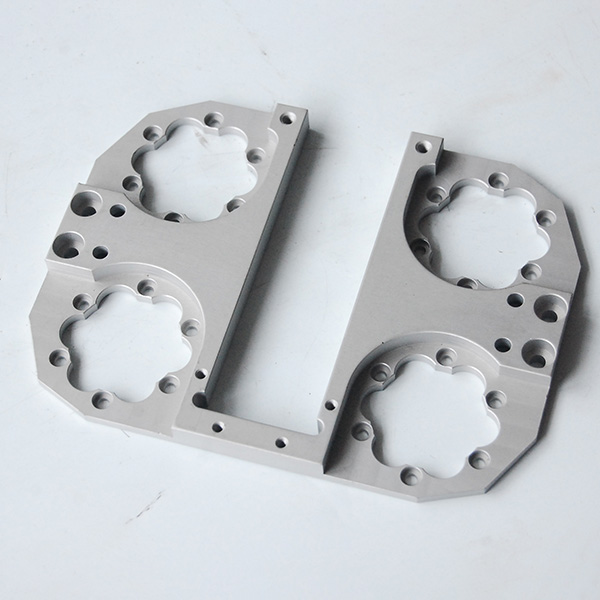

Precision aluminium casting

nrog machined thiab anodized

Precision cam khwb cia aluminium

nrog machined

Hlau cnc

machining qhov chaw