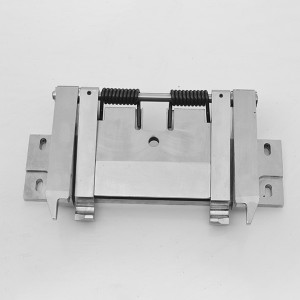

Stamping txheej txheem

Stamping (tseem hu ua nias) yog txheej txheem ntawm kev muab cov ntawv tiaj tus hlau rau hauv daim ntawv dawb los yog coil rau hauv cov ntawv xovxwm stamping qhov twg lub cuab yeej thiab tuag nto ua cov hlau rau hauv cov duab zoo.Stamping muaj ntau yam txheej txheem ntawm cov ntawv hlau tsim, xws li xuas nrig ntaus siv lub tshuab xovxwm lossis stamping xovxwm, blanking, embossing, dabtsi yog khoov, flanging, thiab npib.Qhov no tuaj yeem yog ib theem ua haujlwm uas txhua qhov kev mob stroke ntawm cov xovxwm tsim cov ntawv xav tau ntawm cov ntawv hlau, lossis tuaj yeem tshwm sim los ntawm ntau theem.Cov txheej txheem feem ntau yog ua los ntawm cov ntawv hlau, tab sis kuj tuaj yeem siv rau lwm cov ntaub ntawv, xws li polystyrene.Progressive tuag feem ntau yog pub los ntawm ib lub kauj hlau, coil reel rau unwinding ntawm coil mus rau ib tug straightener rau theem lub kauj thiab ces mus rau hauv ib tug feeder uas txhawb cov khoom mus rau hauv xovxwm thiab tuag ntawm lub predetermined pub ntev.Nyob ntawm qhov nyuaj ntawm ib feem, tus naj npawb ntawm cov chaw nres tsheb hauv qhov tuag tuaj yeem txiav txim siab.

Stamping feem ntau yog ua los ntawm cov ntawv hlau txias.Saib Forging rau kub hlau ua haujlwm.

Stainless hlau: SS304, SS304L, SS316, SS316L, SS303, SS630

Carbon steel: 35CrMo, 42CrMo, ST-52, Ck45, alloy hlau;ST-37, S235JR, C20, C45, 1213, 12L14 carbon steel;

Brass alloy: C36000, C27400, C37000, CuZn36Pb3, CuZn39Pb1, CuZn39Pb2

Aluminium alloy: AlCu4Mg1, AlMg0.7Si, AlMg1SiCu, EN AW-2024, EN AW-6061, EN AW-6063A.

1. Khoov - cov khoom yog deformed los yog khoov raws ib txoj kab ncaj nraim.

2. Flanging - cov khoom yog khoov raws txoj kab nkhaus.

3. Embossing - cov khoom yog ncab mus rau hauv ib tug ntiav ntiav.Siv feem ntau rau kev ntxiv cov qauv zoo nkauj.

4. Blanking - ib daim yog txiav tawm ntawm ib daim ntawv ntawm cov khoom, feem ntau yog ua ib qho dawb paug rau kev ua ntxiv.

5. Npib - ib tug qauv yog compressed los yog nyem rau hauv cov khoom.Ib txwm siv los ua npib.

6. Kev kos duab - thaj tsam ntawm qhov khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob.

7. Stretching - thaj tsam ntawm qhov khoob yog nce los ntawm kev nro, tsis muaj kev txav ntawm sab hauv ntawm ntug dawb paug.Feem ntau siv los ua cov khoom siv lub cev du.

8. Ironing - cov khoom yog nyem thiab txo nyob rau hauv thickness raws ib tug ntsug phab ntsa.Siv rau cov kaus poom dej haus thiab mos txwv daim cartridge.

9. Txo / Necking - siv los maj mam txo txoj kab uas hla ntawm qhov qhib kawg ntawm lub nkoj lossis lub raj.

10. Curling - deforming khoom mus rau hauv ib tug tubular profile.Qhov rooj hinges yog ib qho piv txwv.

11. Hemming - folding ib ntug rau nws tus kheej kom ntxiv thickness.Cov npoo ntawm lub qhov rooj tsheb feem ntau yog hemmed.

Piercing thiab txiav kuj tuaj yeem ua tau hauv cov xovxwm stamping.Progressive stamping yog ib qho kev sib xyaw ua ke ntawm cov txheej txheem saum toj no ua nrog cov txheej txheem tuag nyob rau hauv ib kab los ntawm qhov uas ib txoj hlua ntawm cov khoom hla ib kauj ruam ntawm ib lub sij hawm.

Blackening stamped qhov chaw

Stamping txheej txheem

Steel txias stamping qhov chaw