Hoobkas pheej yig kub Tuam Tshoj Custom Stainless hlau Aluminium Brass Parts Prototype CNC Machining Milling

Peb ntseeg hais tias lub sij hawm ntev kev koom tes yuav ua tau zoo, tsim nyog ntxiv kev pab cuam, kev txawj ntse thiab tus kheej kev tiv tauj rau Hoobkas pheej yig Tuam Tshoj Custom Stainless Steel Aluminium Brass Parts Prototype CNC Machining Milling, Peb zoo siab heev rau koj qhov chaw zoo heev los ntawm peb prospects rau peb cov khoom 'reputable zoo.

Peb ntseeg hais tias kev sib koom ua ke ntev ntev tuaj yeem ua rau muaj txiaj ntsig zoo, tsim nyog ntxiv kev pabcuam, kev paub nplua nuj thiab kev sib cuag rau tus kheej.Tuam Tshoj Cnc Milling, Kev Pabcuam Milling, Thaum koj txaus siab rau ib qho ntawm peb cov khoom tom qab koj saib peb cov npe khoom, nco ntsoov tiv tauj peb rau kev nug.Koj tuaj yeem xa email rau peb thiab tiv tauj peb rau kev sab laj thiab peb yuav teb rau koj sai li sai tau.Yog tias nws yooj yim, koj tuaj yeem nrhiav tau peb qhov chaw nyob hauv peb lub vev xaib thiab tuaj rau peb lub lag luam.los yog cov ntaub ntawv ntxiv ntawm peb cov khoom los ntawm koj tus kheej.Peb feem ntau npaj txhij los tsim kom ntev thiab ruaj khov kev sib raug zoo nrog txhua tus neeg yuav khoom hauv thaj chaw uas cuam tshuam.

Brass alloy yog ib qho alloy ntawm tooj liab thiab zinc, nyob rau hauv proportions uas muaj peev xwm yuav varied kom ua tau ntau yam khoom, hluav taws xob, thiab tshuaj.Nws yog ib qho khoom siv hloov pauv: atoms ntawm ob lub ntsiab lus tuaj yeem hloov ib leeg hauv tib lub qauv siv lead ua.

Cov tooj dag zoo ib yam li tooj liab, lwm cov hlau uas muaj tooj liab uas siv cov tin es tsis txhob zinc.Ob lub tooj liab thiab tooj dag kuj muaj xws li cov feem me me ntawm lwm cov ntsiab lus xws li arsenic, lead, phosphorus, aluminium, manganese, thiab silicon.Keeb kwm, qhov sib txawv ntawm ob lub alloys tsis tshua sib xws thiab meej, thiab niaj hnub kev coj ua nyob rau hauv tsev cia puav pheej thiab archaeology nce zam ob nqe lus rau cov khoom keeb kwm hauv kev pom zoo ntawm ntau "tooj liab alloy".

Brass tau ntev ua cov khoom nrov rau kev kho kom zoo nkauj vim nws ci, zoo li kub zoo li;nws yog siv rau cov tub rau khoom rub thiab qhov rooj.Nws kuj tau siv dav los ua cov khoom siv hluav taws xob vim muaj cov khoom siv xws li muaj qhov qis melting point, ua haujlwm siab (ob leeg nrog cov cuab yeej siv tes thiab nrog cov tshuab tig thiab milling niaj hnub), durability, thiab hluav taws xob thiab thermal conductivity.

Brass alloy tseem nquag siv rau hauv cov ntawv thov uas yuav tsum tau muaj kev tiv thaiv corrosion thiab tsis tshua muaj kev sib txhuam, xws li cov xauv, pob khawm, lub zog, bearings, mos txwv casings, zippers, kav dej, hose couplings, li qub, thiab hluav taws xob plugs thiab sockets.Nws yog siv dav rau cov cuab yeej suab paj nruag xws li horns thiab tswb, thiab tseem siv los hloov cov tooj liab hauv kev ua cov hniav nyiaj hniav kub, zam hniav nyiaj hniav kub, thiab lwm yam imitation hniav nyiaj hniav kub.Cov muaj pes tsawg leeg ntawm tooj dag, feem ntau 66% tooj liab thiab 34% zinc, ua rau nws muaj txiaj ntsig zoo rau cov khoom siv tooj liab, vim nws muaj kev tiv thaiv corrosion ntau dua.Cov tooj dag feem ntau yog siv rau hauv cov xwm txheej uas nws tseem ceeb heev kom tsis txhob tawg, xws li hauv fittings thiab cov cuab yeej siv ze ntawm cov khoom siv hluav taws xob lossis cov khoom tawg.

| Chav kawm | Qhov hnyav (%) | Sau ntawv | |

| Tooj | Zinc | ||

| Alpha tooj dag | > 65 | <35 | Alpha tooj dag yog malleable, tuaj yeem ua haujlwm txias, thiab siv rau hauv kev nias, forging, lossis cov ntawv zoo sib xws.Lawv tsuas muaj ib theem xwb, nrog lub ntsej muag-centered cubic crystal qauv.Nrog rau lawv cov feem ntau ntawm tooj liab, cov tooj dag no muaj xim golden dua li lwm tus.Theem alpha yog ib qho kev hloov khoom ntawm zinc hauv tooj liab.Nws yog ze rau hauv cov khoom rau tooj liab, tawv, muaj zog, thiab me ntsis nyuaj rau tshuab.Qhov zoo tshaj plaws formability yog nrog 32% zinc.Corrosion-resistant liab tooj dag, nrog 15% ntawm zinc los yog tsawg dua, nyob ntawm no. |

| Alpha-beta tooj dag | 55–65 : kuv | 35–45 : kuv | Kuj hu uaduplex tooj dag, cov no haum rau kev ua haujlwm kub.Lawv muaj ob qho tib si α thiab β' theem;lub β'-theem yog txiav txim lub cev-centered cubic, nrog zinc atoms nyob rau hauv nruab nrab ntawm lub cubes, thiab yog ib qho nyuaj thiab muaj zog tshaj α.Alpha-beta brasses feem ntau ua haujlwm kub.Qhov feem ntau ntawm zinc txhais tau hais tias cov tooj dag no ci dua li alpha tooj dag.Ntawm 45% zinc alloy muaj lub zog siab tshaj plaws. |

| Beta tooj dag | 50–55 : kuv | 45–50 : kuv | Beta brasses tsuas tuaj yeem ua haujlwm kub, thiab muaj zog dua, muaj zog dua, thiab haum rau casting.Cov ntsiab lus siab zinc-tsawg tooj liab txhais tau hais tias cov no yog qee qhov ci ntsa iab thiab tsawg tshaj plaws-kub ntawm cov brasses ntau. |

| Gamma tooj dag | 33–39 : kuv | 61–67 : kuv | Kuj tseem muaj Ag-Zn thiab Au-Zn gamma brasses, Ag 30-50%, Au 41%.5Zn8. |

| Dawb tooj dag | <50 | > 50 | Cov no yog nkig heev rau kev siv.Lub sij hawm kuj tseem tuaj yeem xa mus rau qee hom npib tsib xee nyiaj alloys nrog rau Cu-Zn-Sn alloys nrog siab proportions (feem ntau 40% +) ntawm tin thiab / los yog zinc, nrog rau feem ntau zinc casting alloys nrog tooj liab additives.Cov no muaj zoo tsis muaj xim daj ntawm tag nrho, thiab es tsis txhob muaj ntau ntau silvery tsos. |

CuZn36Pb3 tooj dag

ncej qhov chaw nrog gearing

CuZn39Pb1 Brass

machining thiab knurling

CuZn39Pb2 tooj dag

qhov chaw rau valve

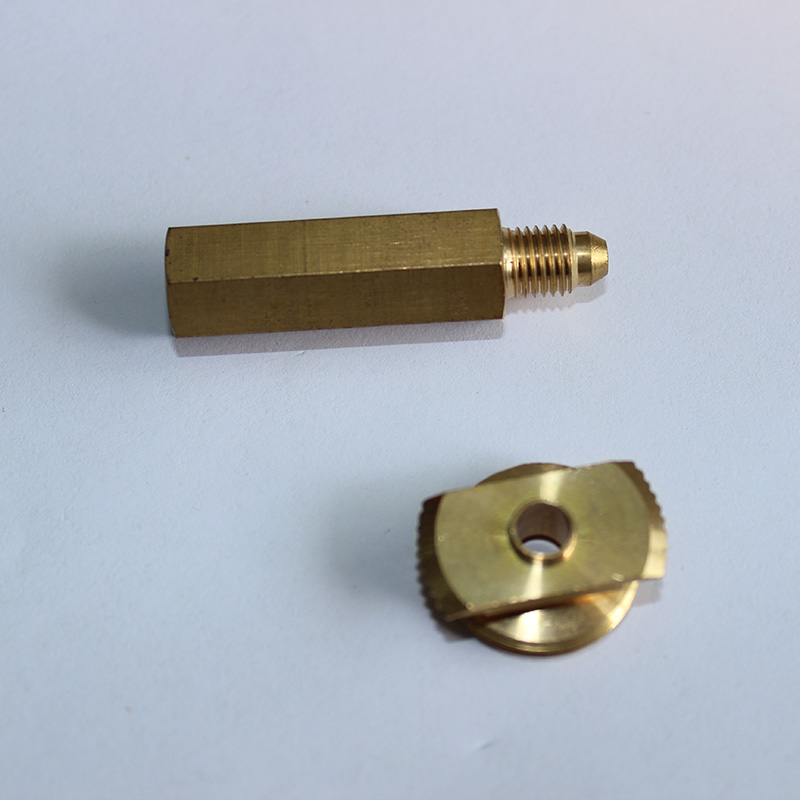

Hexgon tooj dag

machining qhov chaw

CuZn39Pb3 tooj dag machining

thiab milling qhov chaw

CuZn40 Brass

tig rod qhov chaw

CuZn40Pb2 tooj dag

kev pabcuam machining

High precision

tooj dag qhov chaw

Peb ntseeg hais tias lub sij hawm ntev kev koom tes yuav ua tau zoo, tsim nyog ntxiv kev pab cuam, kev txawj ntse thiab tus kheej kev tiv tauj rau Hoobkas pheej yig Tuam Tshoj Custom Stainless Steel Aluminium Brass Parts Prototype CNC Machining Milling, Peb zoo siab heev rau koj qhov chaw zoo heev los ntawm peb prospects rau peb cov khoom 'reputable zoo.

Hoobkas pheej yig kub Tuam Tshoj CNC Milling,Kev Pabcuam Milling, Thaum koj txaus siab rau ib qho ntawm peb cov khoom tom qab koj saib peb cov npe khoom, nco ntsoov tiv tauj peb rau kev nug.Koj tuaj yeem xa email rau peb thiab tiv tauj peb rau kev sab laj thiab peb yuav teb rau koj sai li sai tau.Yog tias nws yooj yim, koj tuaj yeem nrhiav tau peb qhov chaw nyob hauv peb lub vev xaib thiab tuaj rau peb lub lag luam.los yog cov ntaub ntawv ntxiv ntawm peb cov khoom los ntawm koj tus kheej.Peb feem ntau npaj txhij los tsim kom ntev thiab ruaj khov kev sib raug zoo nrog txhua tus neeg yuav khoom hauv thaj chaw uas cuam tshuam.